The Clean Burn Advantage

Reclaiming America’s Energy

It’s time to begin reclaiming American’s energy resources. It’s Time for Clean Burn.

Clean Burn waste oil heater products are engineered from the ground up exclusively to burn waste oils generated by cars, trucks, heavy equipment and other vehicles, and will burn standard fuel oil for added versatility.

Waste oils suitable for recycling through heat recovery include crankcase oil, transmission fluid, and hydraulic fluid.* These petroleum-based and synthetic lubricants present an interesting challenge.

On one hand, waste oils are a burden on the environment when not properly handled. On the other hand, these products have unused energy potential. They can be hauled away and sold as fuel, at a cost. Or they can be burned to produce heat. For those with access to sufficient quantities of waste oil, a Clean Burn waste oil furnace provides a double benefit.

Free Heat and No EPA Liability

It takes a special kind of furnace to efficiently burn the widely varied mixtures of waste oil for use as heat. Clean Burn is that special kind of furnace. There is nothing else like a Clean Burn.

As you are shopping for a waste oil furnace, you are likely to hear someone say, “It’s just as good as a Clean Burn.” You know, when competitors talk about you like that, it says something important. Clean Burn is the acknowledged quality standard of the entire industry of waste oil furnaces. Let us prove it to you.

*Please note: Brake fluid carries a different EPA classification and is not suitable for burning for heat recovery in Clean Burn equipment.

How It Works

See how Clean Burn works – Get the inside scoop on how a Clean Burn furnace will save you money while heating your building for FREE!

We’re here to help answer questions regarding Clean Burn products. For general questions, comments, or requests, please use the form located on this site. For parts/service and international inquiries, please call 800.331.0183.

The Clean Burn Family Of Products

Today Clean Burn continues to lead the world in waste oil combustion equipment and technological expertise.

As the market leader, Clean Burn has more certified engineers on staff constantly improving and creating new waste oil furnaces, boilers, recycling centers and storage tanks than any other manufacturer. A lot of technical expertise is required for the world’s largest selection of waste oil furnaces and boilers.

Another reason Clean Burn is the industry leader is our focus. It’s all we do. We don’t make dryers, parts washers, lifts or any other type of shop equipment.

As you make the important decision on which waste oil furnace to buy, keep that in mind. To Clean Burn, a waste oil furnace is too important to be an afterthought.

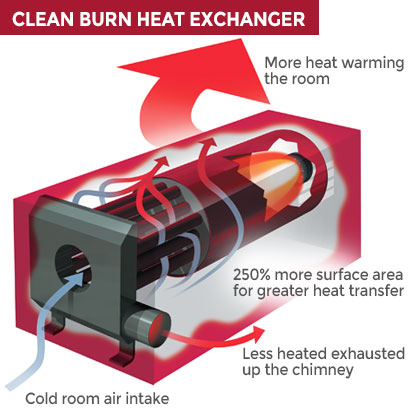

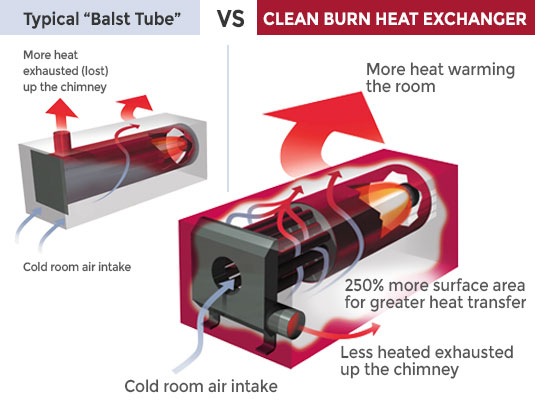

It is simple physics. The more surface area exposed to a combustion chamber, the more heat you will capture. The more time room air circulates around a heated surface, the warmer it becomes.

There’s nothing else in the world like the remarkable Clean Burn Heat Exchanger. Compared to inexpensive Blast Tube furnaces, which feature a simple cylinder shaped combustion chamber, a Clean Burn Heat Exchanger provides approximately 200% more surface area for capturing combustion heat. You get more heat from less oil.

The result is a lower stack temperature, more economical use of your waste oil, easier maintenance and longer service life.

Unlike standard fuel oil, waste oil must be pre-heated in order to ignite properly.

The Clean Burn burner is engineered from the ground up exclusively to burn waste oils, and burns standard fuel oil for added versatility. The pre-heater block heats oil and air to the same precise temperature for efficient combustion.

The mixture is ignited at the burner retention head, where additional combustion air is added, which swirls in a carefully calculated pattern to maximize combustion efficiency and help make flame control easier.

The special retention head creates more air turbulence at the point of ignition to generate a larger, more efficient flame, making operation more reliable.

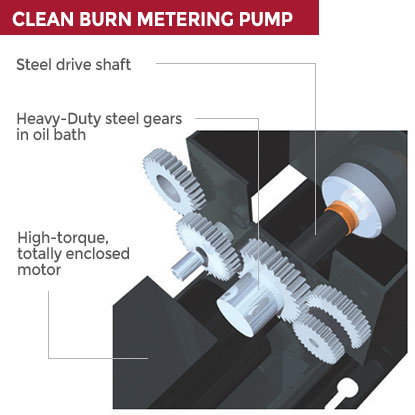

The oil pump is a key component in any waste oil furnace. The Clean Burn Pump is designed as a heavy duty component that doesn’t have to work to the limit of its ability over time. That is why Clean Burns last longer.

Compared with competitive units with plastic gears and overworked electric motors requiring fan cooling, the Clean Burn Pump features heavy duty steel gears encased in an oil bath, and precision assembly to help ensure a very long, very reliable service life. Oil flow is consistently held because precise gear ratios and pump speeds are set for each individual furnace. This maintains correct flow rates no matter what type of oil and viscosity is used and provides for optimum performance.

In short, if you were building your own waste oil furnace, you would choose a Clean Burn Pump, no question.

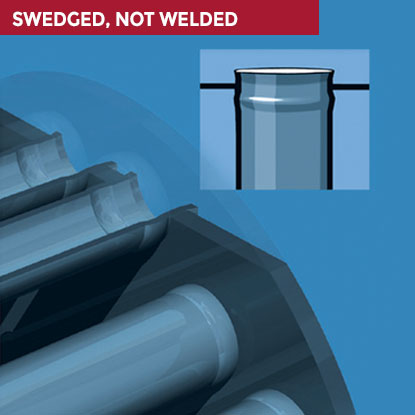

A swedge is a way of joining metal parts without welding. Welded joints are susceptible to cracking and failing in a combustion chamber environment. The tubes in our Heat Exchanger system are not welded together, but swedged, allowing the metal parts to expand and contract with minimum metal fatigue. This means added years of reliability and service life for your Clean Burn furnace.

Measuring the efficiency of waste oil furnaces is difficult because a clean furnace burns more efficiently than a dirty one. This means that the precise efficiency level of any waste oil furnace is constantly changing depending on the amount of ash build up, in addition to other factors.

When comparing “apples to apples,” however, you will find a striking difference with a Clean Burn furnace. Stack temperature. The lower the stack temperature, the greater the furnace efficiency.

Typical Clean Burn Stack Temperature = 450°

Typical Blast Tube Furnace Stack Temperature = 600° to 1000°

In the U.S., nearly all states and municipalities have adopted safety codes, which require that waste oil heating systems be UL listed. Clean Burn has worked closely with UL (Underwriters Laboratories Inc.) for years to help advance the safety standards of waste oil equipment. Our in-house testing facilities are unique in the waste oil equipment industry and are qualified by UL. All Clean Burn furnaces and boilers are UL listed and meet or exceed safety standards as required around the world, including CSA and C-UL in Canada, CE in Europe, GOST-R in Russia, and ERMA in New Zealand.

Clean Burn has worked closely with UL to develop UL-listed waste oil ducted central furnace systems. For applications where heating ducts are required, it is important to make sure that the manufacturer has obtained UL approval.

Clean Burn Distributors are experts in the technology and science of recovering usable heat from waste oils. They are businessmen. They are hard working specialists who know their craft. Many Clean Burn Distributors do nothing else but sell and service Clean Burn waste oil furnaces.

Look to your Clean Burn Distributor for the finest customer service, integrity and, of course, outstanding Clean Burn products.

Three reasons why your Clean Burn Distributor should be your first call.

- Help in choosing the right equipment

- Installation that meets every local code

- Service that is responsive and unequaled

The Clean Burn Service Advantage

Your Clean Burn Distributor carries most commonly used service parts and can usually provide them overnight if needed. To order, contact your Clean Burn Distributor.

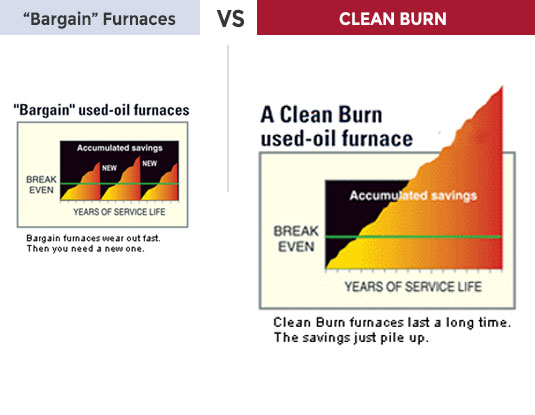

The higher initial cost of a Clean Burn buys you a waste oil furnace that will last longer, perform more reliably, be easier to clean and maintain, cost less to service, and give you a far greater return on your investment than any other waste oil heating system, period.

You get the world’s most advanced technology for recovering heat from waste oils. With Clean Burn you get better engineering, heavier materials, unrivaled craftsmanship, and unequaled sales and support service for the specialized job of heating with waste oils.